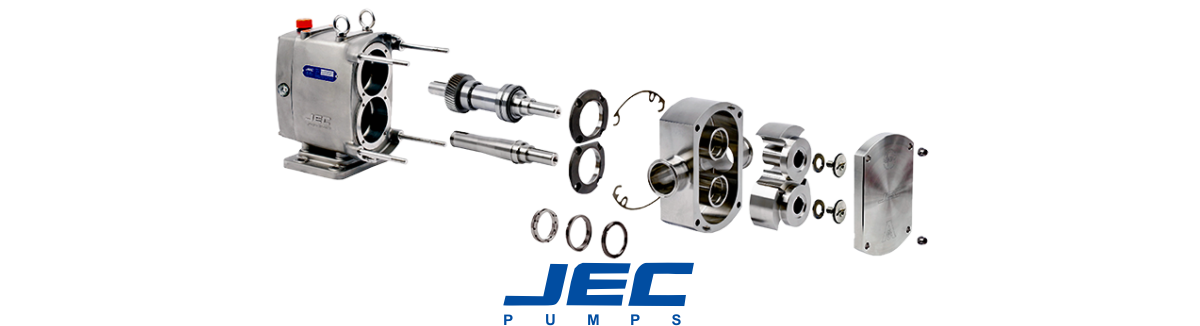

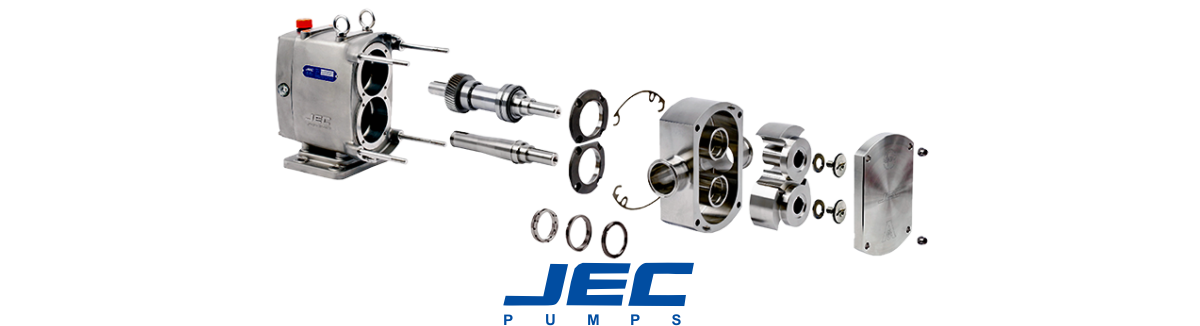

Infinity Pumps & Systems Pvt. Ltd. offers Circumferential Piston Pumps / Rotary Piston Pumps from JEC. They provide this range of high quality Rotary Piston Pumps in India at competitive prices. These Circumferential Piston Pumps in India comes with 3A and EHEDG certification. Infinity Pumps & Systems Pvt. Ltd. also provides other range of JEC Pumps in India, Graco pumps in India, Albin Pumps in India and TUFFGEAR ® Pumps.

For further detailed information download free pdf.